From electric vehicles (EVs) to consumer electronics and large-scale energy storage systems, batteries have become the backbone of modern technology. Their performance directly affects product reliability, user safety, and overall efficiency. As industries continue to push for higher standards, the way batteries are manufactured has become just as critical as the materials used.

Battery cell stacking is a crucial step in battery cell manufacturing, offering clear advantages over traditional alternatives.

Higher Energy Density & Design Flexibility

One of the key benefits of battery cell stacking lies in its ability to increase energy density. By layering electrode sheets in a flat, precise arrangement, stacking allows for better use of available space within the cell. This means more active material can be packed into the same volume, delivering higher energy capacity without increasing size.

The result is that, under the same unit volume or unit weight, stacked cells can store more electrical energy than traditional wound cells. This advantage is particularly critical for applications where size and weight constraints are non-negotiable. For example, portable electronic devices require slim and lightweight designs. And electric vehicles demand compact, energy-dense packs to extend driving range without compromising vehicle weight.

In practice, stacking technology also enables the flexible selection and combination of lithium battery units with different performance characteristics. Manufacturers can optimize the arrangement and connection of multiple smaller units rather than relying on a single large-capacity cell. This approach not only maximizes spatial efficiency but also enables fine-tuned customization tailored to the specific requirements of the end product.

Better Thermal Management

Heat management is a critical issue in battery performance and safety. Poor thermal regulation can lead to reduced efficiency, faster degradation, and in extreme cases, safety risks such as thermal runaway.

Battery cell stacking provides a structural advantage by ensuring consistent alignment and uniform pressure distribution across the electrode layers. It can maintain a temperature variation of less than 3°C across the cell, a key factor in reducing thermal stress.

By maintaining the temperature difference within a narrow range, stacked battery cells not only operate more safely but also ensure electrochemical balance among electrode layers, resulting in slower capacity fade over time.

Mechanical Stress Distribution

A less visible but highly important benefit of cell stacking technology is the way it manages mechanical stress within the electrodes. In stacked cells, each electrode sheet remains flat and evenly pressed, which helps distribute the mechanical load across the entire layer. This even distribution prevents specific parts from being overstressed, reducing the chance of cracks, delamination, or accelerated material wear during repeated charge and discharge cycles.

Battery Cell Stacking vs Battery Cell Winding: What are the Differences?

The advantages of cell stacking technology, from higher energy density and improved thermal stability to reduced mechanical stress, clearly demonstrate its value in modern battery manufacturing. Yet, to fully appreciate why stacking is gaining traction, it is important to consider it alongside the cell winding method, which has been widely used for decades.

Compared with battery cell stacking vs winding, these two techniques serve the same purpose of building reliable lithium-ion cells, but they approach the challenge with very different structures.

| Comparison Aspect | Battery Cell Stacking |

Battery Cell Winding |

|

Mechanical Stress |

Uniform stress, less electrode damage | Bending points, potential hotspots, and fatigue |

|

Energy Density |

Higher due to better space utilization |

Lower due to the central void and curved geometry |

|

Internal Resistance |

~10–15% lower due to multi-tab, shorter current path |

Higher, single-tab, longer path |

|

Thermal Management |

Even heat spread, < 3 °C gradient |

Uneven, > 10 °C gradient in some regions |

|

Design Flexibility |

More Flexible to meet a wide range of formats (pouch, blade, prismatic) |

Limited configuration options |

| Manufacturing Complexity | More complex, slower, and more costly manufacturing |

Less complex, faster, and more cost-effective manufacturing |

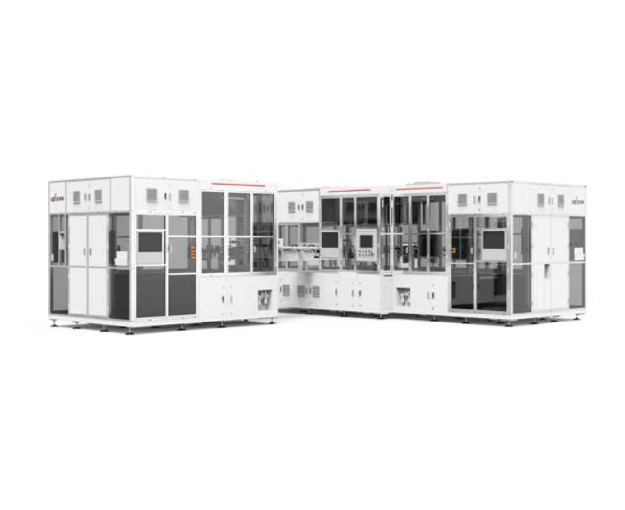

Introducing LEAD’s Digital Cell Cutting and Stacking Machine

Above all, battery cell stacking technology has several benefits in energy density, thermal management, and balanced mechanical stress. highlighting the critical role of precision and automation in modern battery manufacturing. To fully leverage these benefits, manufacturers need reliable, high-performance equipment that can handle the delicate alignment and pressure requirements of stacked electrodes.

To meet these demands, LEAD’s Digital Cell Cutting and Stacking Machine offers a fully integrated solution designed for precision, efficiency, and reliability.

- Integrated Processes: Combines electrode unwinding, cutting, stacking, and unloading in a single streamlined workflow, reducing manual handling and improving consistency.

- Sealed Stacking Transfer Belt: Prevents electrode contamination during the critical stacking process.

- Vision System Inspection: Detects electrode defects and measures dimensions in real time, with non-contact NG (no-good) discharging to ensure quality.

- High-Precision Positioning: Vision-guided alignment with an accuracy of 0.02mm, ensuring perfect electrode placement.

- Intelligent Commissioning: Supports one-key commissioning, one-key reset, power-on self-test, automatic adjustments, and preventive maintenance.

- 2-Stage Adaptive Separator Tension Control: Maintains stable tension within 5% during stacking, with peak deviation limited to 12%, ensuring safety and uniformity.

By integrating these advanced features, LEAD’s Digital Cell Cutting and Stacking Machine enables manufacturers to fully leverage the advantages of battery cell stacking, including improved energy density, enhanced thermal management, and balanced mechanical stress.

For more information, please contact LEAD directly or visit LEAD’s official websites!

"*" indicates required fields

Reference

- https://beyond-battery.com/en-us/blogs/beyond-battery-blogs/why-stacking-is-overtaking-winding-for-high-rate-batteries

- https://www.tobmachine.com/blog/comparative-analysis-of-stacking-vs-winding-processes-in-lithium-battery-manufacturing_b129