“We are very interested in working with Bayern Innovativ and various research and educational institutions to jointly develop new process technologies and address challenges such as energy efficiency, circular economy and workforce training.”

Yanqing Wang

Chairman, LEAD GROUP

As a global leader in intelligent equipment solutions for the new energy industry, Lead Intelligent Equipment provides innovative technologies and services to many of the world’s top automotive, new energy, and technology enterprises. In this interview, Mr. Wang Yanqing, Chairman of LEAD Group, elaborated on the company’s core competitiveness and shared its vision for collaboration and future development in the Bavaria region.

Below is the full text of the interview.

How does Lead Intelligent Equipment (LEAD) assess the development of battery cell production in Europe and what role would you like to play in this market?

Yanqing Wang (YW): We see Europe on a strategic path to build a robust, sovereign battery ecosystem. Driven by the EU’s Green Deal, the increasing adoption of electric vehicles and the goal of energy independence, the production of battery cells is moving from pilot projects to industrial production. LEAD is playing a key role in this transition.

With the opening of our plant in Naila, Bavaria, in 2022, we have created a strong local base. Since then, we have grown our German team to over 250 employees, created a center of excellence and are deeply embedded in the European production system. This enables us to offer turnkey battery production systems tailored to EU regulations and operational expectations, covering lithium-ion, sodium-ion and solid-state technologies.

What are LEAD’s core competencies, and what types of partnerships or stakeholders are of particular interest to you in Bavaria?

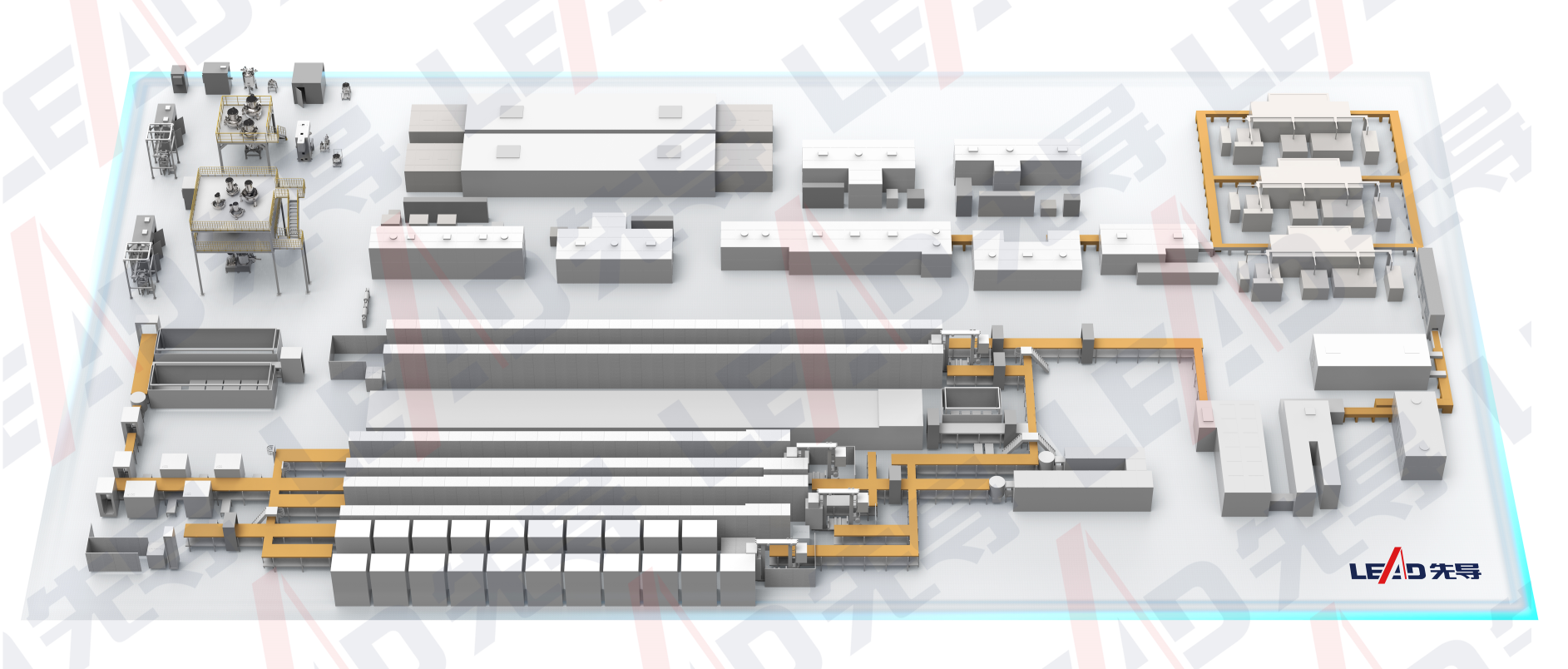

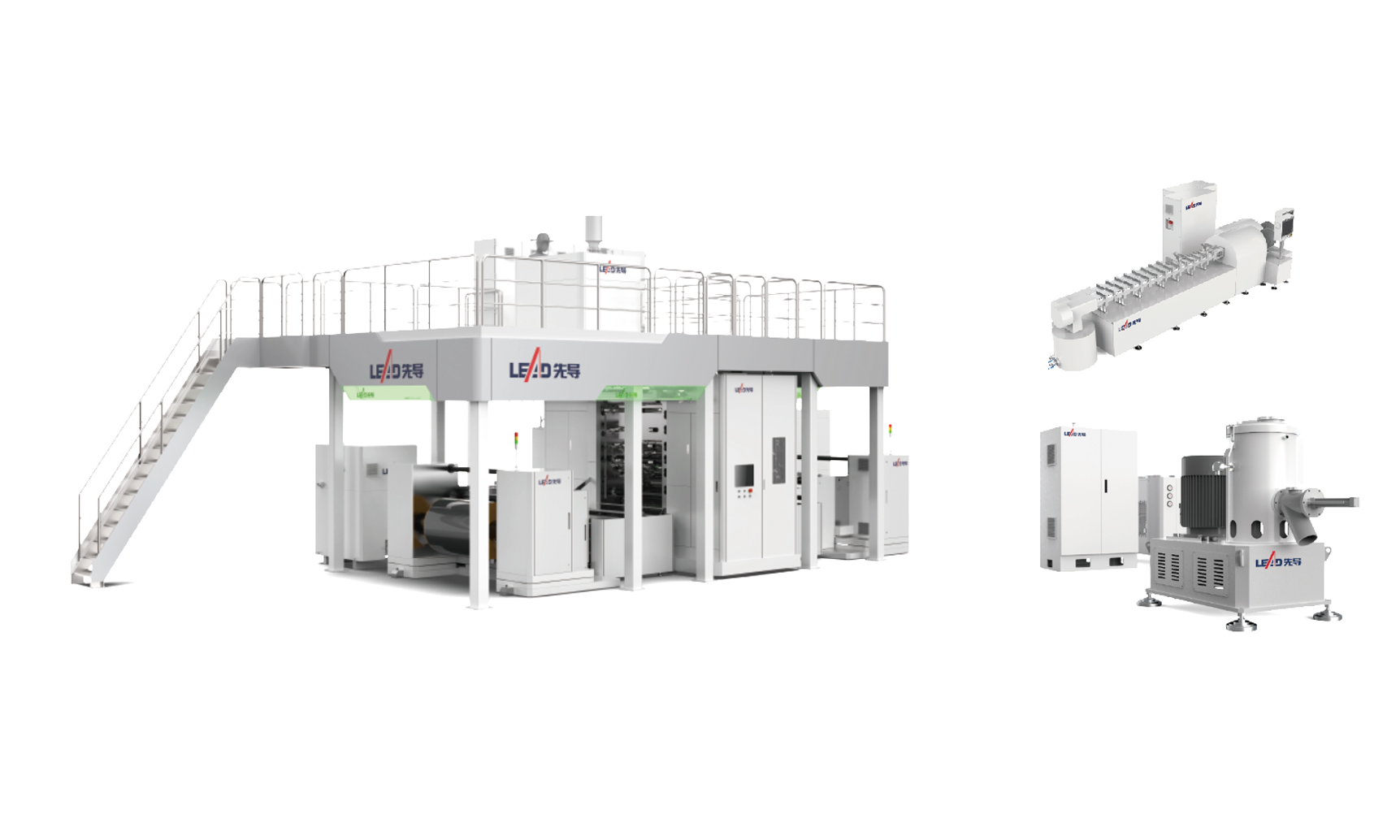

YW: Our core competencies cover the full spectrum of intelligent battery manufacturing. As a global leader in smart manufacturing solutions for the new energy economy, we offer customized production lines that cover the entire battery value chain – from slurry mixing and coating to cell stacking/wrapping, electrolyte filling, forming and smart logistics.

Our expertise is based on deep process integration for all common and new chemical processes: NMC, LFP, sodium-ion, semi-solid and all-solid-state batteries. LEAD is one of the few companies in the world able to supply end-to-end production lines for solid-state batteries, including specialized processes such as SSE membrane handling, high-precision stacking and interface technology.Our core competencies are based in particular on intelligent, modular solutions for adaptive, highly efficient manufacturing, turnkey services for the entire spectrum with end-to-end ownership, in-depth industry and process knowledge as well as innovation-driven and quality-oriented engineering.

We are particularly interested in strategic partnerships with automotive manufacturers and Tier 1 suppliers who are accelerating their battery production. We are also interested in innovative start-ups looking for support in scaling up production, as well as technology clusters and research institutions exploring the frontiers of battery science.With our European headquarters and logistics center already located in Germany, we want to contribute to the Bavarian battery ecosystem through local service, technical collaboration and talent development. Together, we can shape a more sustainable and smarter energy future.

What is the role of the Center of Competence in Naila?

LEAD’s Center of Competence (CoC) in Naila serves as a critical technological and operational bridge between Chinese innovation and the needs of European industry. There, LEAD’s global capabilities are localized, adapted and integrated into the unique regulatory, cultural and technical context of Europe.

More specifically, the CoC acts as a gateway for the adaptation of innovations to European standards, such as CE/UL compliance for safety and environmental regulations, integration with European industrial IT systems (e.g. MES, SCADA, etc.), as well as the integration of Chinese innovations into European industry. More specifically, the CoC acts as a gateway for adapting innovations to European standards such as CE/UL compliance for safety and environmental regulations, integration with European industrial IT systems (e.g. MES, SCADA), mechanical/electrical redesign to comply with EU workplace and factory standards, and the adaptation of user interfaces and documentation to EU languages and company cultures.

In addition, the CoC has extensive in-house production and machining capabilities, including CNC milling, turning, welding and cabinet assembly. This allows us to quickly develop and manufacture prototypes and localized machine parts and assemblies. We can also adapt standard Chinese equipment designs to project-specific European requirements and reduce lead times and transportation costs for heavy or complex mechanical systems.

Last but not least, the CoC has a complete service and training system as well as a central logistics warehouse and is therefore perfectly equipped to meet the needs of our customers.

Which advanced technologies should be favored for battery production in the future, and what role does LEAD play in this?

As the battery industry moves towards higher energy density, safer chemical processes and more environmentally friendly manufacturing, scaling up next-generation production technologies is becoming increasingly important. This includes dry electrode deposition and solid-state battery assembly due to their transformative potential. Both technologies can significantly reduce energy consumption, eliminate hazardous solvents and support climate goals – making them essential to the industry’s sustainable future.